In industries today, especially here in the UAE, efficient storage and logistics aren’t just nice to have, they're absolutely essential. Whether it's keeping up with large-scale agricultural demands, retail distribution, or fast-moving warehouses, businesses need reliable systems in place to handle goods quickly and safely.

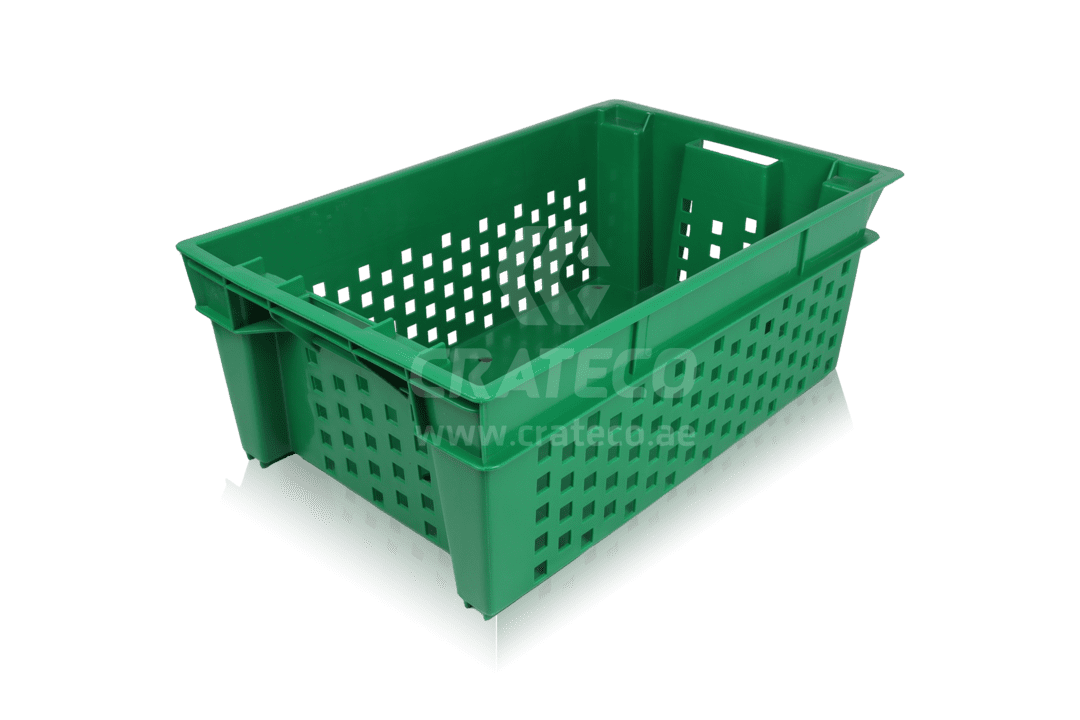

That’s where plastic crates come in. These tough, reusable containers might seem simple, but they’re a backbone for countless operations. They are durable, moisture- and chemical-resistant, yet remain lightweight for easy handling. In our experience across sectors like food supply or industrial manufacturing in the UAE, plastic crates have proven to be a smart, no-fuss solution for day-to-day logistics.

In this blog, we’ll break down the evolution, benefits, applications, types, and challenges of plastic crates, and how they enhance logistics and supply chains across industries.

Storage and material handling methods have come a long way from bulky, rigid containers to efficient, adaptable solutions. Traditionally, industries relied on wooden boxes or metal bins to store and transport goods. While these materials offered strength, they also came with drawbacks such as heavy weight, susceptibility to rust or rot, and limited hygiene.

Over time, as industries grew more dynamic and global logistics demands increased, businesses began seeking smarter alternatives. That’s where plastic crates entered the picture.

Wooden and metal containers were once the norm, but they often posed challenges in terms of weight, maintenance, and cost. Wooden crates could splinter or absorb moisture, while metal containers could rust or dent. In contrast, modern plastic crates are lighter, resistant to weather and chemicals, and easier to clean making them a better fit for today’s fast-moving industries.

The shift to plastic was driven by a need for efficiency, hygiene, and reusability. Plastic crates offer longer lifespans, lower maintenance, and better compatibility with automated systems. In the UAE and beyond, industries embraced plastic crates as a solution that balances cost-effectiveness with practical functionality especially in sectors like food, retail, logistics, and manufacturing.

When it comes to choosing the right storage solution, plastic crates stand out for a number of practical reasons.

Here are some of the key benefits that make them a smart investment for any industry.

Durability and long lifespan

Plastic crates are built to last. Unlike wood or metal, they resist rust, splintering, and corrosion over time. Their strong construction ensures long-term performance, even with repeated use in tough environments.

Lightweight but strong

Despite being lightweight, plastic crates can handle heavy loads without cracking or warping. This balance makes them easy to carry and ideal for fast-paced industrial or warehouse settings.

Hygienic and easy to clean

Plastic is non-porous and easy to sanitize, making it a preferred material for industries like food and pharmaceuticals. A quick wash or wipe-down is usually enough to maintain cleanliness.

Stackability and space efficiency

Many plastic crates are designed to stack securely or nest when empty. This helps save valuable floor space and keeps storage areas neat and organized.

Cost-effectiveness in the long term

Though plastic crates might have a higher upfront cost than cardboard or wood, they pay off over time. Their long-lasting nature and ability to be reused minimize the need for constant replacements.

Weather and chemical resistance

Plastic crates perform well in extreme weather and are resistant to many chemicals. Whether used indoors or outdoors, they maintain their shape and strength even in harsh conditions like the UAE's heat.

Whether it's moving goods across a warehouse or shipping them internationally, plastic crates help simplify every step of the logistics process.

Plastic crates are built tough to handle the demands of daily use in transit and storage. Their solid construction helps prevent breakage, compression, and other common types of damage, keeping goods safe throughout the journey. Many crates are also resistant to pests, mold, and bacteria, making them ideal for transporting sensitive items like food and pharmaceuticals.

Thanks to their stackable and nestable design, plastic crates make excellent use of available space whether in a warehouse, delivery truck, or shipping container. This not only improves storage efficiency but also reduces handling time. Foldable or collapsible models offer added savings by taking up minimal space when not in use.

Plastic crates often come with built-in handles and ergonomic designs, making them easy to carry and maneuver. Their standardized sizes ensure they work smoothly with pallets, forklifts, and automated systems, which speeds up loading, unloading, and overall movement of goods.

Because plastic crates last longer than many alternatives, they help reduce the cost of frequent replacements. Their lightweight nature also cuts down on fuel use during transport. And when they eventually wear out, most crates can be recycled helping businesses reduce their environmental footprint.

With options to integrate barcodes or RFID tags, modern plastic crates support real-time tracking and inventory control. This added visibility helps businesses streamline their supply chains, reduce errors, and improve operational efficiency from start to finish.

Due to their strength, adaptability, and affordability, plastic crates are extensively used across various industries in the UAE and globally. From food storage to industrial transport, they provide practical solutions tailored to each sector’s specific needs.

Here’s how different industries benefit from using plastic crates:

Agriculture

Farmers depend on plastic crates for harvesting and transporting fruits, vegetables, and other fresh produce. The crates protect delicate items from bruising and damage, and their ventilated designs help maintain freshness during handling and storage.

Food & Beverage

Hygiene is critical in the food sector, and plastic crates deliver. They are used to store and transport dairy products, meats, baked goods, and beverages. Their easy-to-clean surfaces and non-porous material make them ideal for sanitary food handling.

Retail & E-commerce

Retailers and online sellers use plastic crates for organizing inventory, displaying goods, and managing returns. Returnable transit packaging (RTP) models offer reusable, cost-saving options for deliveries and back-end logistics.

Logistics & Transportation

Plastic crates support smooth operations across the supply chain. Their standardized sizes, stackable design, and sturdy construction make them a top choice for shipping, warehousing, and last-mile delivery.

Pharmaceutical

The pharmaceutical industry uses plastic crates to transport medications, medical devices, and lab supplies under hygienic conditions. These crates help ensure product integrity while meeting industry safety standards.

Other Industrial Sectors

Heavy-duty plastic crates are common in the automotive, electronics, and manufacturing sectors. They’re used to store and move parts, tools, and components efficiently and securely in demanding environments.

By offering both sustainability and reusability, plastic crates enable a circular approach to packaging where products are reused, recycled, and kept in use for as long as possible.

Reduced Packaging Waste: Reusable plastic crates eliminate the need for single-use alternatives such as cardboard or wooden boxes, drastically cutting down on landfill waste.

Resource Conservation: Their use reduces dependency on raw materials like wood, water, and paper-based products, making them more environmentally responsible.

Lower Carbon Footprint: Over time, reusable crates generate fewer emissions than single-use packaging especially when factoring in their lifespan and recyclability.

Efficient Transport: Their uniform design, stackability, and lightweight build allow for better space usage in trucks and containers, saving fuel and lowering emissions.

Recyclability at End-of-Life: Once no longer usable, many plastic crates can be recycled and repurposed into new plastic products, completing the sustainability loop.

Hygiene Compliance: Their easy-to-clean surfaces make them suitable for food, pharmaceutical, and healthcare use without contributing to contamination or waste.

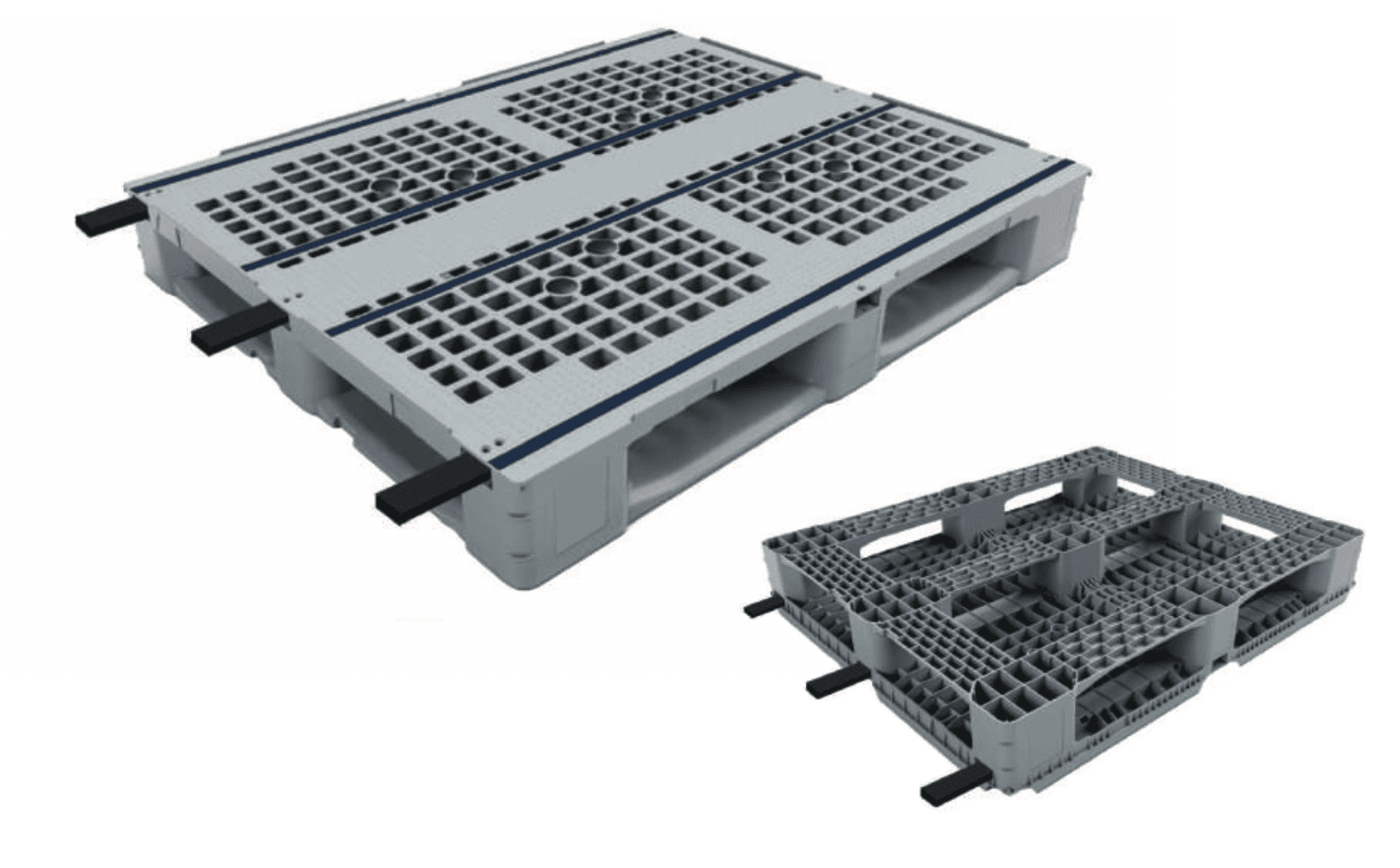

High Durability: Designed to withstand multiple handling cycles, plastic crates endure rough transport, stacking, and extreme temperatures without damage.

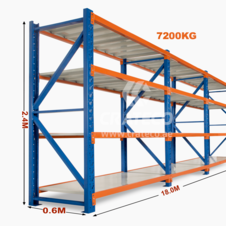

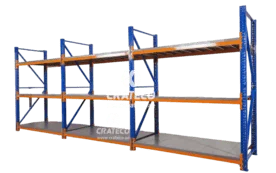

Standardized Designs: Crates are often built to fit seamlessly with pallets, automated systems, and warehouse racking simplifying returns and reuse.

Trackability: With the help of RFID tags and barcodes, businesses can monitor crate usage, location, and condition throughout the supply chain.

Cost-Efficient in the Long Run: While initial costs may be higher, reusable crates reduce recurring expenses on disposable packaging and waste management.

Crate Pooling Systems: Many industries adopt crate-sharing models, increasing usage efficiency and minimizing excess crate production.

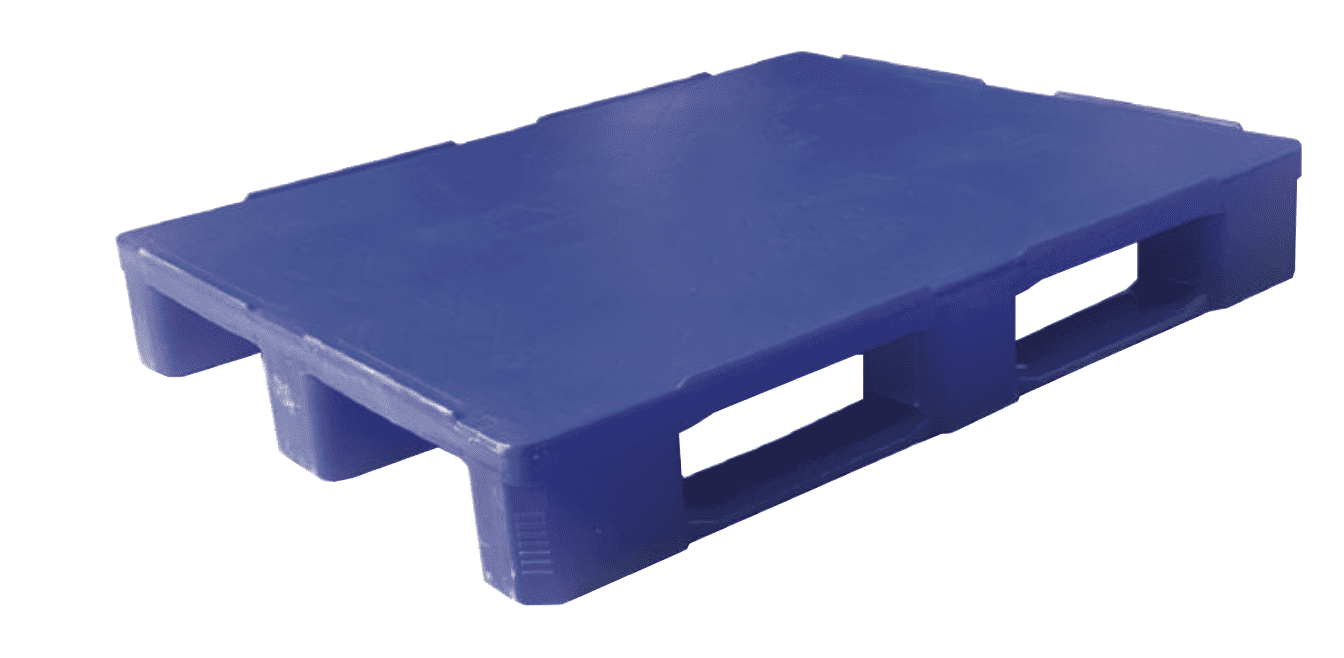

Plastic crates come in a variety of types and configurations each tailored to meet specific industry demands.

From lightweight stackables to heavy-duty industrial bins, selecting the right crate type improves storage efficiency, product protection, and supply chain performance, especially in active logistics hubs like the UAE.

Here’s an overview of the most widely used types:

Stackable Crates: These crates are designed to stack securely on top of each other, making them ideal for maximizing vertical space in storage facilities and during transport.

Nestable Crates: When empty, nestable crates fit inside each other to save space a major advantage for reverse logistics and return transport systems.

Foldable Crates: Foldable crates can collapse flat, reducing storage space when not in use. They're widely used in e-commerce, distribution centers, and seasonal supply chains.

Perforated (Ventilated) Crates: Designed with holes for airflow, ventilated crates are ideal for transporting fresh produce, dairy, seafood, and bakery items where circulation and breathability matter.

Solid (Closed) Crates: Fully enclosed design that protects contents from dust, light exposure, and external contaminants.

Jumbo Crates: Large-capacity crates designed for bulky or heavy items, frequently used in agriculture, automotive, and industrial applications.

Spare Parts Bins: Small, durable bins ideal for organizing and storing hardware, tools, fasteners, or machinery components in workshops and factories.

Crates with Lid: Lidded crates offer added protection against moisture, dust, and tampering especially valuable for secure storage or long-distance transport.

Bottle Crates: Specially designed to securely hold glass or plastic bottles, these crates prevent breakage during handling and transport in beverage industries.

Heavy-Duty Industrial Crates: Built for high-load performance, these crates withstand rough handling and extreme environments, often used in manufacturing and logistics.

Plastic crates aren’t just for storage they boost speed, safety, and cost-efficiency across supply chains, from UAE warehouses to global hubs.

Here’s a more detailed breakdown of how they contribute to supply chain efficiency:

Plastic crates are superior durable than cardboard, reducing damage from crushing or impacts during transit. This leads to fewer product losses and returns some suppliers report up to 50% less product waste.

With standardized shapes, plastic crates stack and nest efficiently to save space in warehouses and transport. Foldable versions reduce return load bulk, and their lightweight design cuts fuel use and emissions.

Plastic crates are also compatible with barcodes and RFID tags, enabling real-time inventory tracking and enhanced visibility throughout the supply chain. This visibility improves forecasting, reduces stockouts and overstocking, and speeds up order processing. Clear or translucent plastic crates further simplify operations by allowing quick visual inspection of contents without the need to open them.

4. Sustainability and Cost Savings

Reusable plastic crates replace single-use packaging, reducing waste and supporting environmental goals. Their long lifespan lowers replacement frequency and cost, while their efficiency in transport and storage minimizes labor and logistics expenses over time.

While plastic crates offer many advantages, it’s important to consider a few practical challenges before adopting them into your operations. Here's what businesses in the UAE and beyond should keep in mind:

Choosing the Right Crate Type:

Selecting the appropriate crate whether stackable, foldable, ventilated, or heavy-duty depends on your specific products, handling process, and industry requirements. Selecting an unsuitable crate type can result in operational inefficiencies, increased handling issues, or potential damage to goods.

Storage Space When Not in Use:

When crates are empty, they can take up valuable warehouse or floor space. Nestable or collapsible options can help, but planning for off-season or surplus storage is essential.

Maintenance and Replacement Planning:

Even durable plastic crates can wear down over time. Regular inspection, cleaning, and maintenance help extend their lifespan. Having a replacement plan ensures continuity without downtime in logistics.

Plastic crates are not just practical storage containers, they are essential tools driving modern storage and logistics efficiency. In industries across the globe, and especially within the growing UAE logistics industry, these reusable solutions play a vital role in achieving long-term operational and environmental goals. By reducing packaging waste, conserving natural resources, and cutting costs across supply chains, plastic crates contribute to a more sustainable and streamlined system.

Businesses turn to plastic storage containers for their unmatched durability and resistance to heavy loads, rough handling, and temperature variations. Their hygienic surfaces make them ideal for food-grade and pharmaceutical logistics, while their stackable and nestable designs maximize warehouse and transport space. Whether used for agriculture, retail, manufacturing, or e-commerce, plastic crates offer a versatile solution that meets industry-specific requirements.

Backed by a long lifespan and made from recyclable materials, plastic crates support sustainable packaging efforts while lowering total operational costs. For companies looking to boost supply chain efficiency, reduce environmental impact, and invest in reliable infrastructure, partnering with a trusted plastic crate manufacturer is key.

Ready to upgrade your storage and logistics with reliable, industry-grade plastic crates? Explore our full range of solutions at Crateco Pack LLC and take the first step toward smarter, more sustainable operations.

In short, plastic crates are more than containers; they are a smart, scalable, and future-ready foundation for any logistics operation.