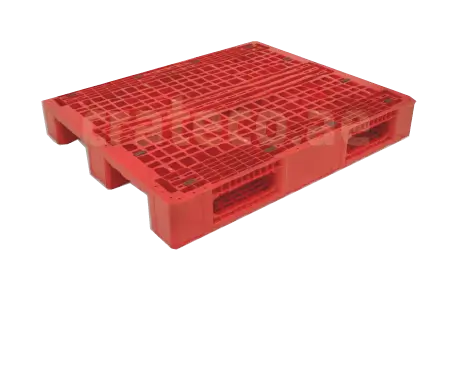

However, any business that requires movements of goods with hygienic importance, let be it raw materials, semi-finished goods, or finished goods, should ensure Plastic Pallets are used for safety and easy handling of the goods. on the other hand, also reduces the need for any other packaging materials.

To achieve the best results, it is essential to select the right pallet, as there are various sizes, types, and structures available in the market. Crateco always advises clients to consult with our service team to determine the most suitable plastic pallets in Qatar, plastic pallets in Oman, plastic pallets in Bahrain, plastic pallets in Kuwait, plastic pallets in Salalah, plastic pallets in Muscat, and plastic pallets in Sohar based on their specific needs.

It is used in all industries, however, please see the major industries using plastic pallets.

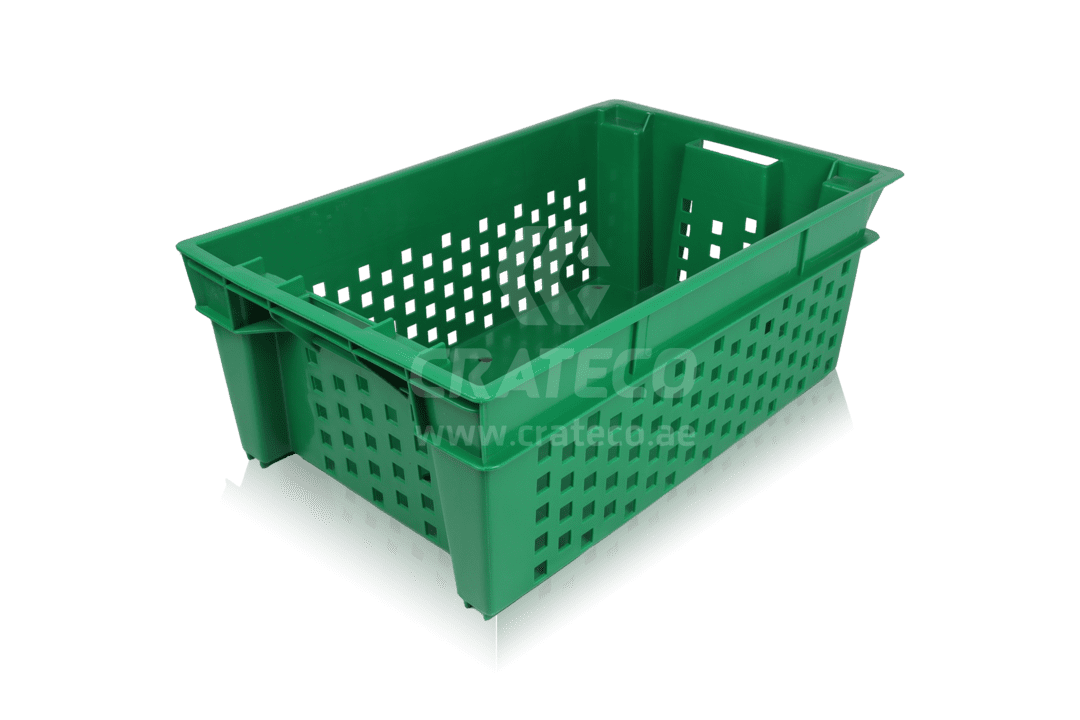

Food Processing & Distribution:

It is the right choice for food industries as it protects from fungus and other spoils happen in wooden pallets.

Pharmaceutical Industry:

Plastic Pallets are the perfect choice for pharmaceutical industries as they have to maintain a particle-free and sterile environment for instance even the smallest fragment can contaminate the product.

Automotive Industry:

The automotive industry requires the use of the highest quality material handling equipment in the long run and heavy-duty plastic pallets assist greatly in this area.

By choosing the right dimension, type, and structure we can find the right pallet for our use. The Crateco team is pleased to be at your disposal to check the special requirements of your individual application.

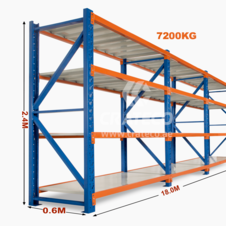

Dimensions of Pallets:

Firstly, customers can choose the size based on the products they are keeping on pallets and warehouse or storage space that suits the size of the pallet. However, crateco can supply any size of plastic pallets. Please see the few common sizes:

Secondly, there are 3 major types of plastic pallets from which customers can choose the right one.

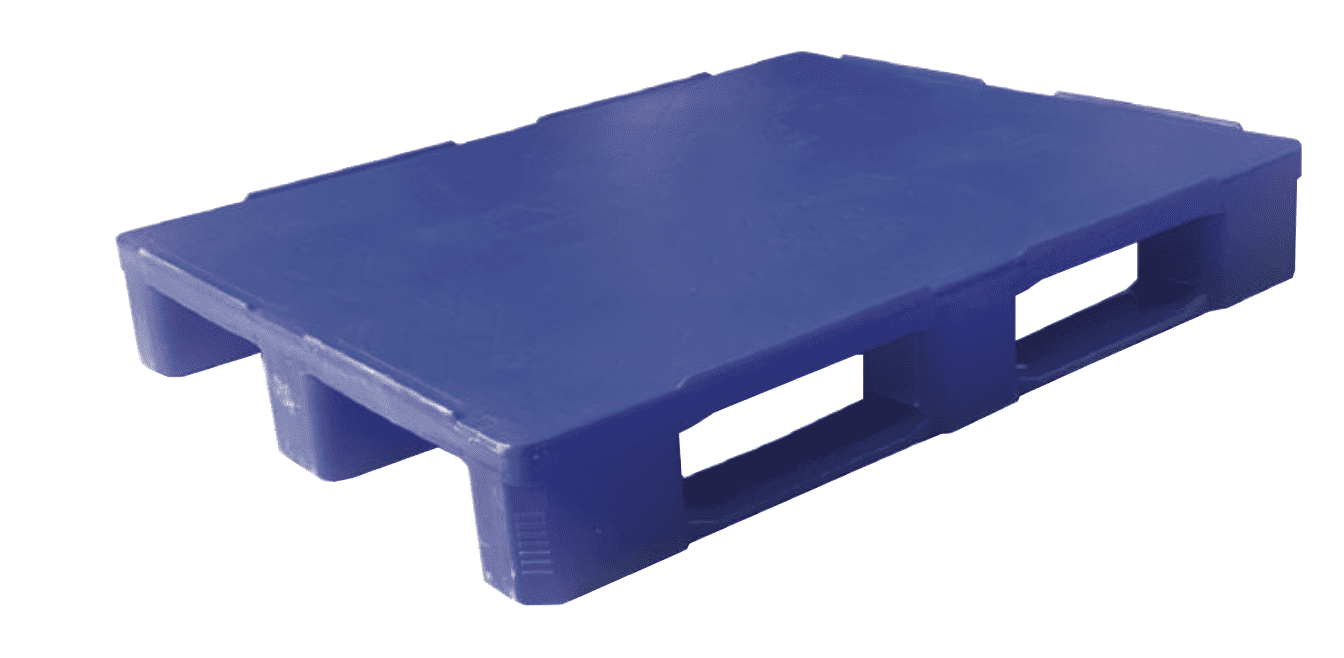

Flat Pallets or Hygiene Pallets:

Majorly used in food industries as its top and bottom surface is flat, therefore it’s very easy to clean, and the chances of getting food particles in between the pallet ventilation parts and thereby bacteria, odors, and other contaminants absorption is avoided.

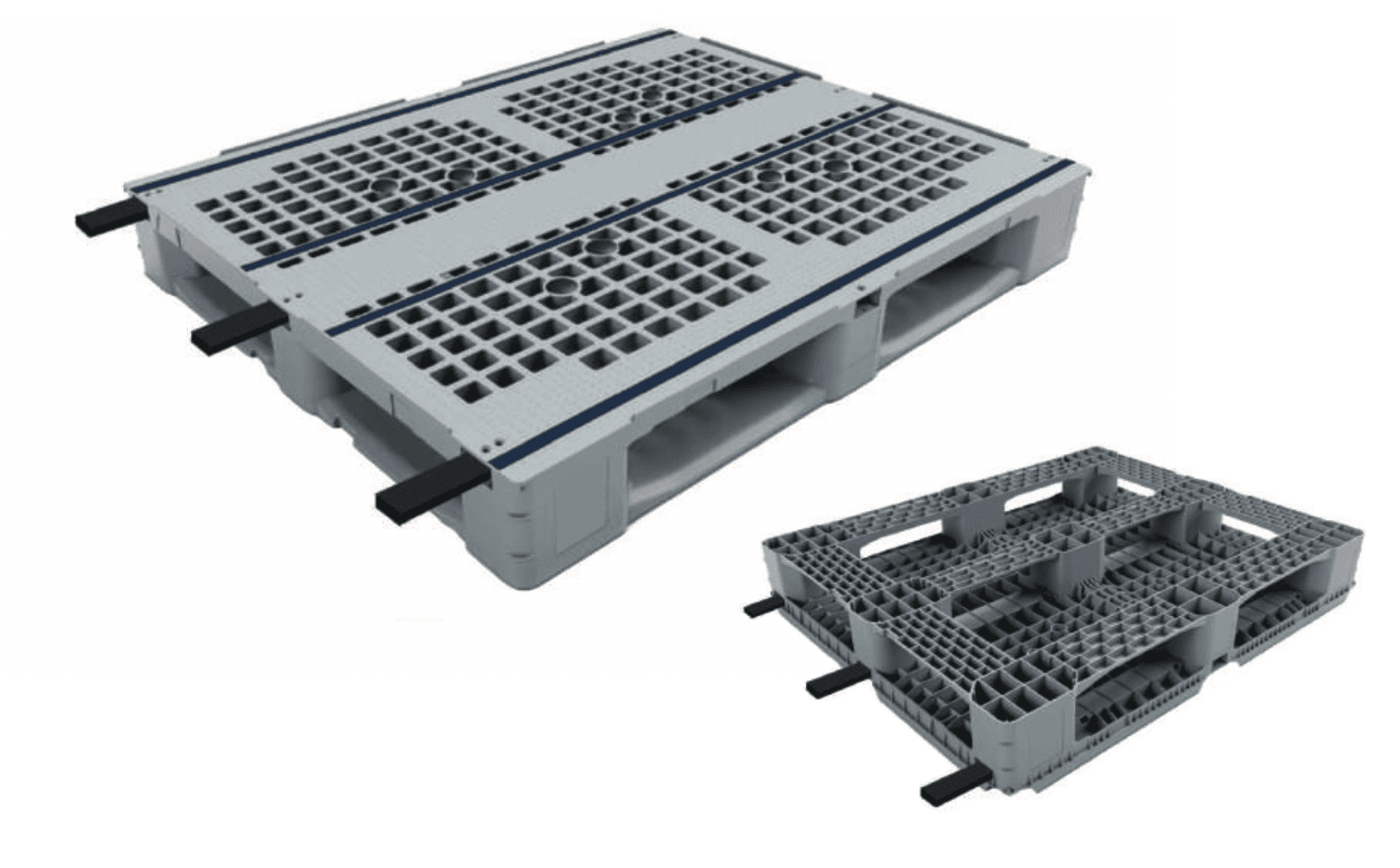

Ventilated Pallets:

The product which required air circulation chooses ventilated pallets. However, this is the common pallet in the market.

Reversible Pallets:

Pallets with both surfaces being the same are reversible pallets. Most importantly these are usually heavy-duty pallets and are majorly used for the dynamic loading of rice flour, maida flour, and other kind of raw material or goods packed in sacks.

The structure or shape of pallets is categorized into a few, they are:

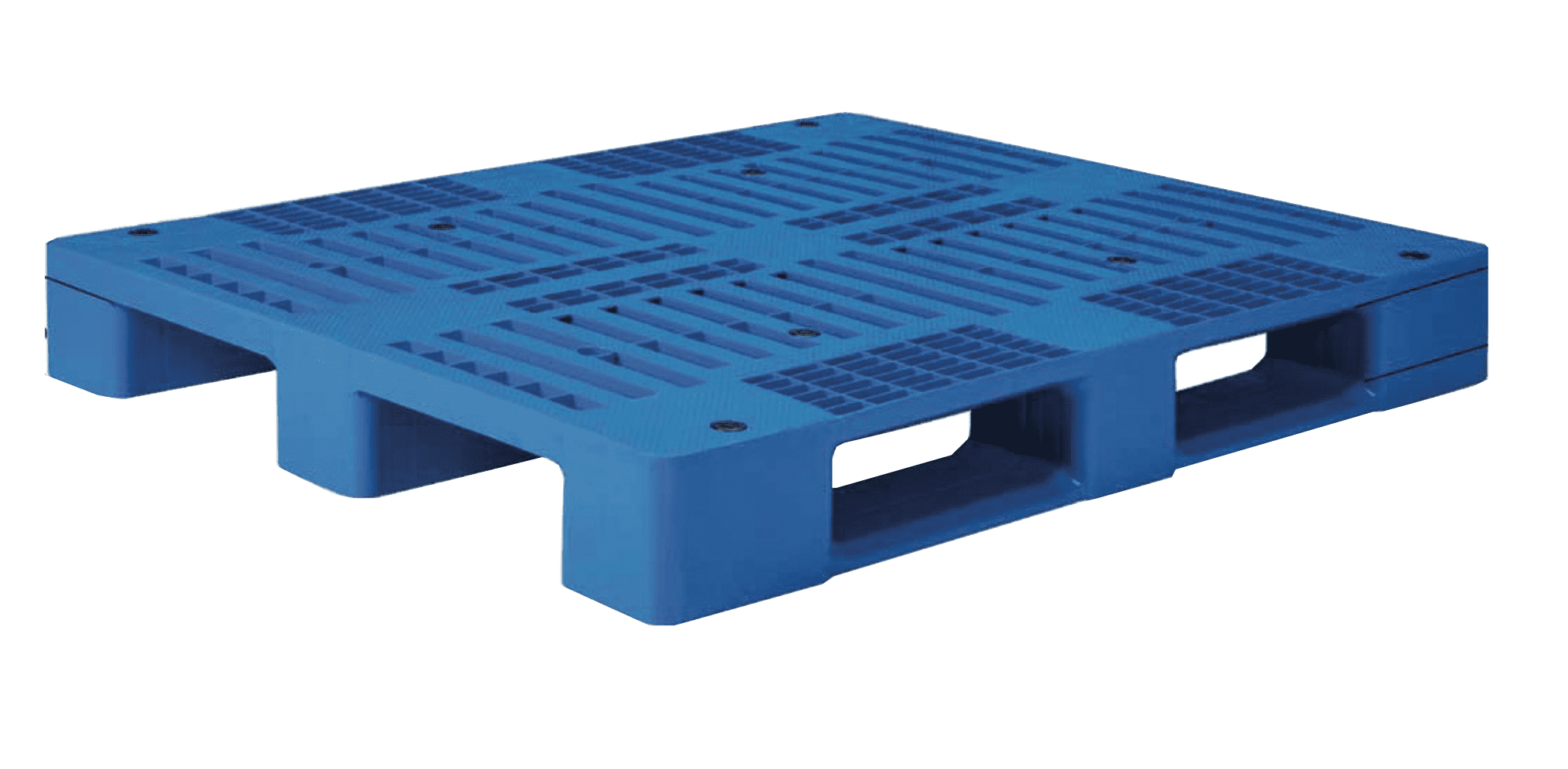

3 Runner Pallets:

3 runner pallets are very easy for the usage of Hand Jack, Forklift, and Stackers. However, it is suitable if the movement of pallets is more and dynamic capacity is required below 1.5 tons.

5 Runner Pallets:

5 runner pallets help to get more strength in Dynamic and Racking Loading, and a little easier for the usage of Hand Jack and Forklift compared to 6 Runner Pallets. These are usually medium-duty pallets.

6 Runner Pallets:

Above all 6 runner pallets gives more strength to the pallets and most heavy-duty and racking pallets are 6 Runner Pallets.

9 Leg Pallets:

9 leg pallets with no runner in the structure. However, these pallets are suitable only for light-duty pallets and are not recommended for Racking or heavy dynamic purpose. But, plastic pallets used to keep permanently in cold storage and cold storage vehicles or refrigerated vehicles or freezer vehicle are 9-leg pallets.

There are many categories of plastic pallets, for example:

To ensure the longevity of plastic pallets in Bahrain, plastic pallets in Muscat, and plastic pallets in Sohar, follow these best practices:

Avoid exposure to sunlight and away from fire and radiation, otherwise, it may lead to aging and short service life

Avoid Rain

Storage: store in a dry indoor area, especially for pallets reinforced by steel tubes inside

Avoid changing the temperature of pallets, such as keeping them in cold storage or freezer for some time and later in normal temperature.

Don’t Slide or drop the pallets from heights or stacks

Avoid throwing goods on plastic pallets this way.

Never apply spot pressure on pallets.

Everyone secure goods with strapping tape or stretch wrap to prevent dislodging of goods

Subsequently, always load goods in a layer by layer & uniformly distributed manner for maximum stability

Importantly keep a constant speed when forward & withdraw or up & down in the forklift operation process. For example, No Sudden Brakes, No Flashback, No Clash! However ensure fork has an appropriate length and angle, over 2/3 in depth at least and the maximum spacing in width.

Above all, don’t use a forklift to push pallets across the floor, as the bottom will get damaged.