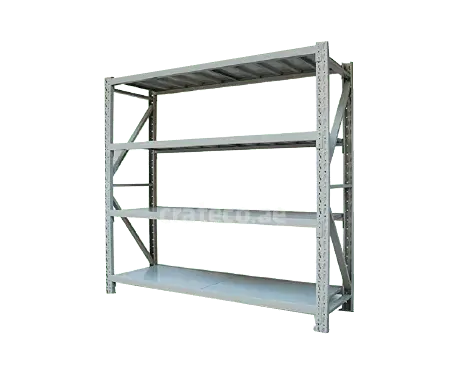

Industrial Racks are used to help keep all your devices safe and secure and avoid any damage. They are a smart way of storing your devices and keeping them in the right place. Racks come in a variety of shapes and sizes and can provide a huge amount of space and are available in different configurations.

One of the biggest benefits of Industrial Racks is that they are easy to use, you can put them together, configure them, and move them around your premises with ease.

Industrial racks also come in a variety of sizes and configurations; this means that you can create a diverse set of different racks.

1. Slotted angle racks

Due to their strength, lightness, and affordability, slotted angle racks are frequently utilized in every industry. When it comes to product management, they have significantly improved efficiency and made more space for new materials. A forklift can be used to move and transport them with ease as well.

Let’s examine 5 fantastic advantages of using slotted angle racks for your company:

Solid Construction:

Nothing compares to slotted angle racks for strength and longevity. They are made of steel, which makes them incredibly strong and well-built. They also have a longer lifespan than any other form of available carrier due to this. With the additional necessity of minor maintenance, its sturdy construction ensures longevity and may meet the needs of any warehouse for years to come.

Maximum Space Utilization:

Space is a critical factor that cannot be overlooked when it comes to the growth of your company. The best option for increasing the available space in your warehouse with minimal overhead is slotted angle racks. You may store a range of items easily and neatly with the help of this practical storage solution. Additionally, they have the ability to triple a warehouse’s storage capacity!

Freedom to Customize:

Without any trouble, slotted angle racks can be customized to match your company’s demands. They can be tailored to fit the unique needs of your warehouse in terms of size, height, and width. Additionally, you can order custom racks to fit your needs in terms of space and price.

Provides a Polished Look:

Your firm will look more professional if you meticulously organize all of your merchandise in your warehouse. It will give your store a unique, professional identity. This will be very beneficial for attracting clients, creating a feeling of identity, and building a solid brand.

Increase in Productivity:

Slotted angle racks make it simple to handle, store, and locate merchandise. The layout makes it easier to arrange things, and you can arrange items according to how frequently you will use them. The workers will be able to simply identify the pieces they need thanks to this. By allowing your employees to concentrate on the current task, you’ll not only save time but also enhance production.

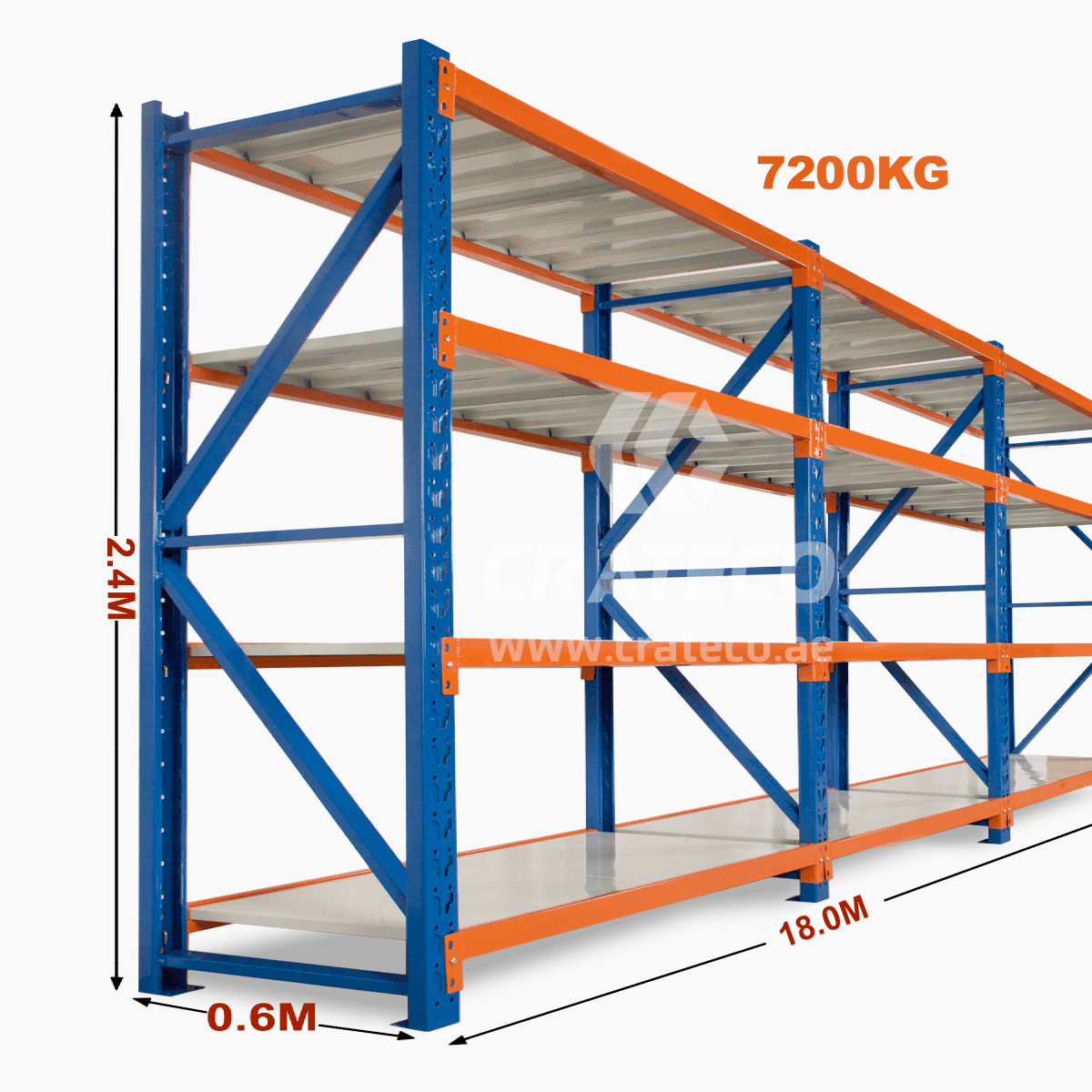

2. Medium-duty racks

A medium-duty rack is necessary if you choose to build a cost-effective warehouse. Steel pipes, hardwood planks, plastic tubing, and other lengthy, hefty, or oddly shaped materials are perfect for storing on these racks. Our medium duty racks ensure smooth operations in the warehouse, preventing structural issues when removing items from these storage units.

Planning business growth is made easier by purchasing a rack system from us. Utilizing such a cantilever racking system from us has a number of related advantages. Here, we go over the top five advantages of employing a cantilever racking system that we designed and made specifically for you.

Ideal for storing long items

The medium-duty rack is perfect for holding a variety of objects and materials whose use and construction are commonly underestimated. Our cantilever racks offer several special advantages and use that conventional racking is unable to supply because they are made for longer, more slender things.

The storage of longer, more slender items like steel racks, beams, protruding pieces of wood, or even pre-packed furniture is considered in our medium-duty rack design. Cantilever racks are the ideal approach to store any tall, thin objects you need to be kept off the floor because of their open design and total length. While these items are typically difficult and awkward to store using normal shelving and rack strategies.

Easily accessible and flexible

Our medium-duty rack consists of two or fewer racks from either side of a long I-bar, with nothing directly above and no typical “shelf” to talk about. This more open design considers much easier access, especially on the higher racks with forklifts or equivalent equipment. Additionally, the design allows for the placement and removal of substantially more explicitly marked items, allowing you to store more products and explicitly marked items on medium-duty racks without worrying that a variety of pallets of items that you do not immediately need may cover them.

Economical and saves time

We can provide you with a medium-duty rack that will enable you to work more quickly while using less energy. The layout makes it easier to store and maintain products, allowing workers to find what they need more quickly or stack items on the racks considerably more effectively than with other types of racks. By creating extra room in different places and considering deeper storage to hold more items, the expanded storage area gives both longitudinally and in-depth also considers the efficient use of space.

Easy to assemble

One of the easiest and fastest stockpiling options to assemble are medium-duty rack systems. It is a fantastic choice for various warehouse environments because of how simple it is to assemble. The majority of medium-duty rack systems employ a slot-and-tag assembly technique, in which a tag on the horizontal support is secured into an appropriate gap on the vertical portion.

When the racks are not needed, storing them is made simple by the straightforwardness that permeates this quick and easy establishment.

Larger structures typically use more intricate bolt-on horizontal bars, although they are simple and quick to construct. The configuration of medium-duty racks is usually modular as well, allowing a few units to be bolted together to expand an existing structure.

Lasts for years

It will undoubtedly persist for many years. In order to ensure the highest quality and endurance, we create the racks using only the best materials.

3. Heavy-duty racks

Heavy Duty Pallet Racking is the solution you need if you own a retail shop and discover that your goods take up more space than you have. A practical way to increase the amount of storage space in a warehouse is using heavy duty pallet racking. Pallet racks can be installed in the warehouse wherever they are most needed, enhancing throughput and changing floor layouts. With the help of pallet racks, you may define your space better and make lanes of shelves for easy forklift operation.

Let’s examine some advantages of heavy-duty racks:

Maximise Space:

Lack of room is a common issue that many warehouses face. Warehouse managers should store as many products as they can to maximize the usage of their limited floor space from a financial standpoint.

By implementing a heavy-duty racking system, businesses can utilize unused vertical space rather than just adding more storage to the original floor plan area. By storing as many products as feasible, warehouse capacity can be maximized, saving both time and money.

Increase Efficiency:

Lack of room is a common issue that many warehouses face. Warehouse managers should store as many products as they can to maximize the usage of their limited floor space from a financial standpoint.

By lowering storage space, more floor space can be set aside for workers and moving equipment like trucks and forklifts. By doing so, the number of impediments on the warehouse floor would be reduced, enabling workers to do their tasks more quickly.

Improve Safety:

The likelihood of occupational dangers and injuries will be significantly reduced in an effective and organized warehouse. In addition to increasing your storage capacity, heavy-duty racking solutions enable you to construct larger hallways and industrial tracks. Since there would be fewer tripping hazards along the routes, employee safety would increase.

Additionally, heavy-duty racks can be fixed to the warehouse floor to increase stability and reduce the likelihood that it will collapse in the event of an emergency.

Convenience:

Structural pallets that are easy to install and disassemble are used by heavy-duty racks. Because activities can continue as usual in the warehouse during this time, installing the racking system is made simpler.

We hope you enjoyed learning about the different types of industrial racks and their benefits. As you can see, there is a lot to consider when choosing the right rack for your needs. However, with a little research and careful planning, you should be able to find the perfect solution for your business. Thanks for reading!