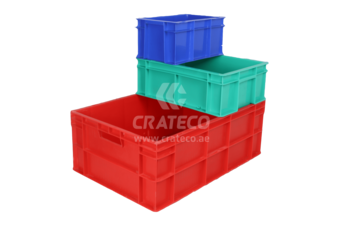

In recent years, the food industry has preferred the use of plastic pallets due to the necessity to securely handle, transport, and store perishable food in conditions of acceptable sanitation and cleanliness in order to reduce waste and ensure that goods reach consumers in good condition.

Despite only being around for a few decades, plastic pallets are rapidly replacing wood pallets as a hygienic, effective alternative for shipping goods that are prone to contamination.

The two industries with the most regulations are food and pharmaceuticals. In one way or another, they are both goods intended for human consumption. Therefore, from the time they leave the manufacturing facility until the end user acquires them, these products must be secure, uncontaminated, and kept in a climate-controlled environment.

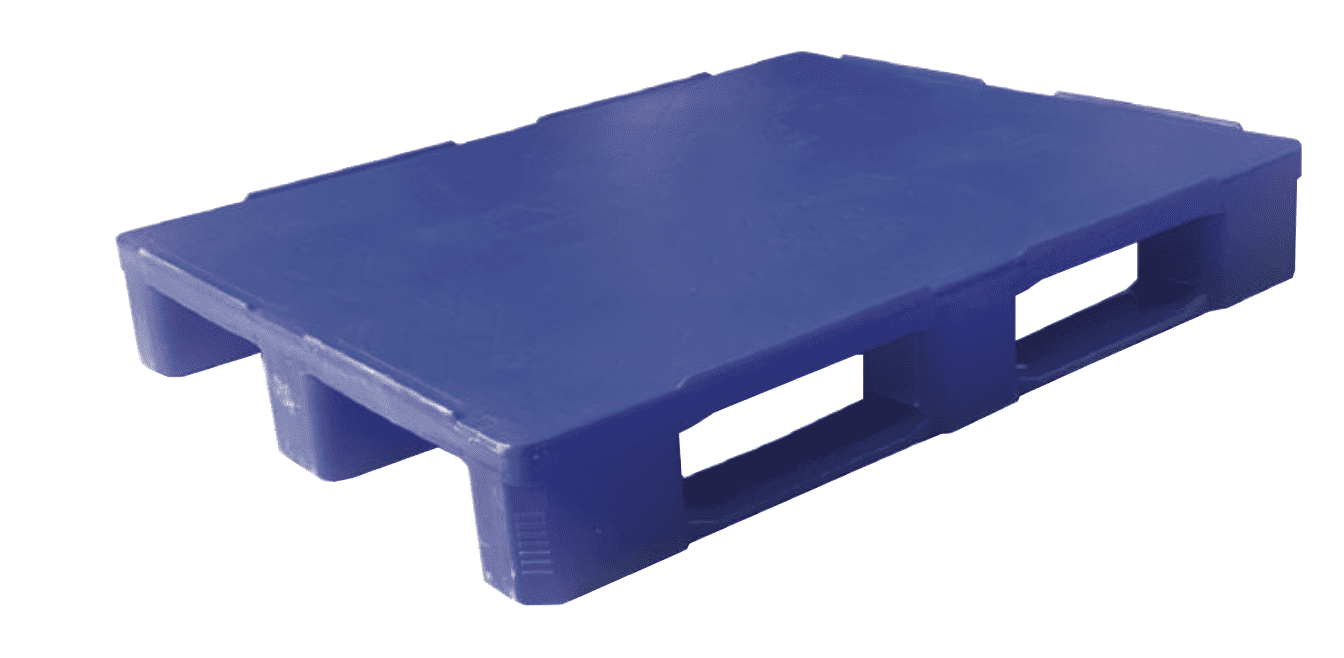

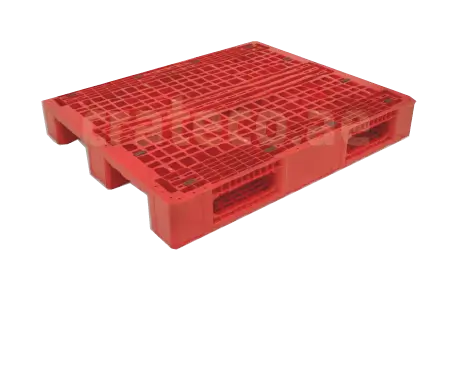

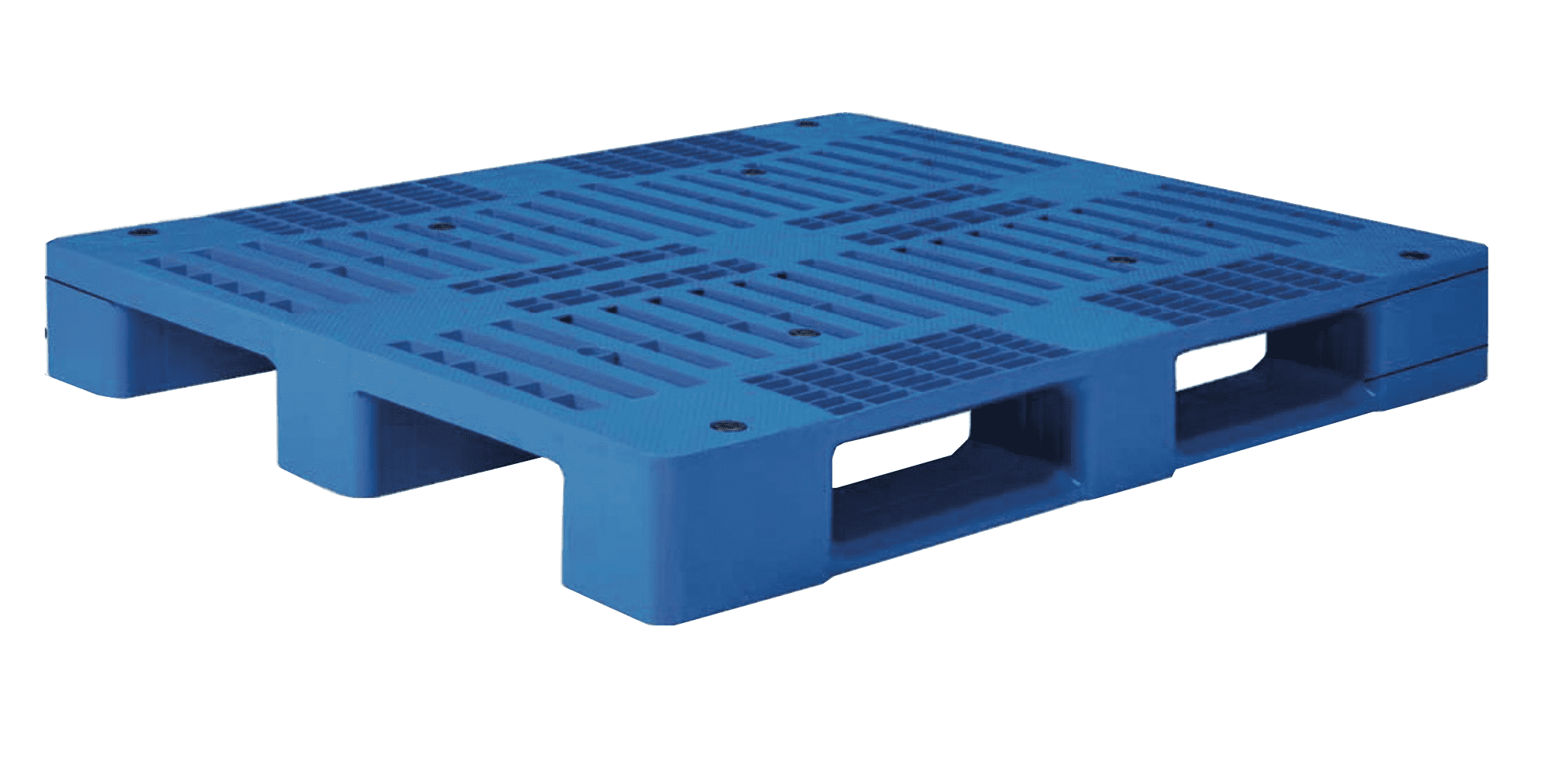

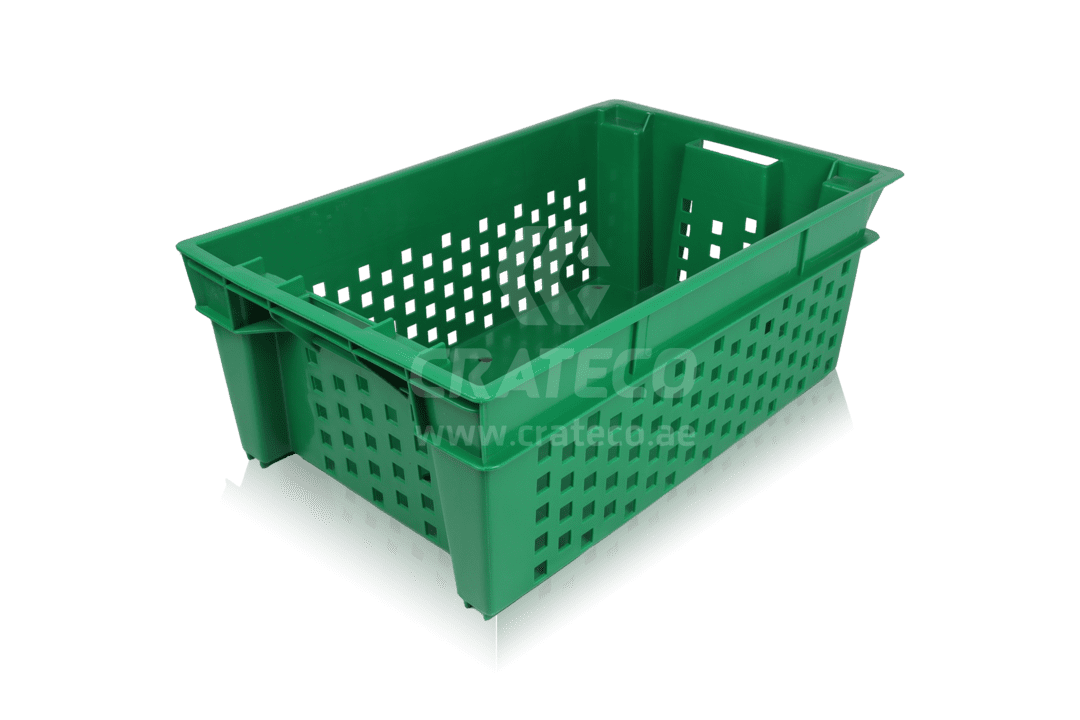

In the food business, hygiene is the main justification for using plastic pallets. Plastic is a substance that is not porous and does not absorb liquids. Additionally, the cleanroom plastic pallets used in the food sector have a unique shape with smooth surfaces that can be thoroughly cleaned without leaving debris in awkward places like corners or curves.

Plastic pallets are still advised for carrying processed food to supermarkets even if it is delivered in primary packaging like aluminum cans or foil shrink wrap. Using retail display pallets means the products need less handling because they may be transported on the same pallet from the warehouse to the store backroom to the supermarket aisle. Crateco closed bottom pallet supplier in Dubai supplies all types of pallets.

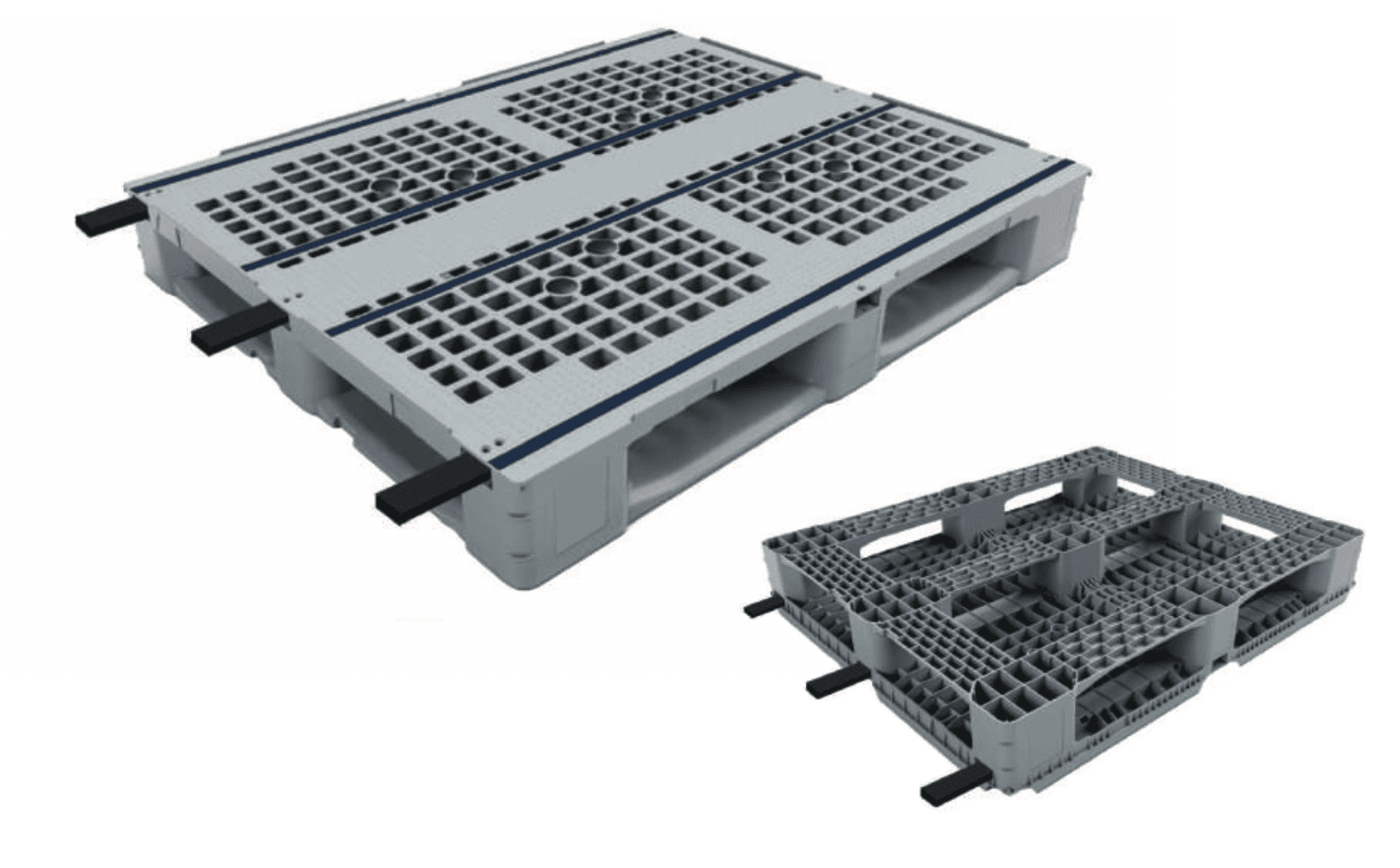

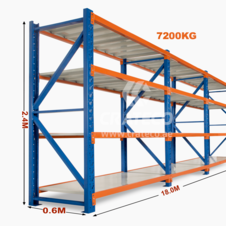

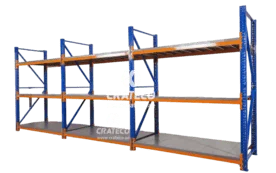

Speaking about handling, the global tendency is to reduce manual labor as much as possible in all supply chains. As a result, your business needs packing materials that can be handled by logistical equipment like pallet trucks, forklifts, and tug trains.

The design of wooden pallets did not take automation and machine handling into consideration. They are not designed to work with these devices, and they cannot endure this kind of use. Comparatively, the unique design elements of plastic pallets make it possible for logistical equipment to lift, push, and pull them without harming them. Get in touch Crateco Pack LLC.

Plastic pallets are made by expert package manufacturers like Logistic Packaging with the demands of clients, both big and small businesses, in mind. And the most important requirement is to reduce expenses without sacrificing quality or safety.

And plastic pallets aid your business in achieving this objective in a number of ways:

Crateco Pack LLC, as the top Hygienic pallets Manufacturer in UAE, suggests that the capability of customizing a pallet to meet your products and logistical flow is another significant advantage of using plastic pallets in the food business. In order to create plastic pallets, virgin PP is injected into a mold. Additionally, a skilled manufacturer of packaging can create molds that adhere to exact specifications.

Plastic pallets are not covered by this rule. You won’t have any problems shipping your goods through customs or any of the other checkpoints along the way. As a result, you can design pallets with unusually shaped feet, greater load bearing capability, legs, skids, or rims of varied heights surrounding the deck.

The plastic pallet is the ideal and necessary logistics solution for the food sector because of its high durability, resistance, reuse, and waterproof nature.