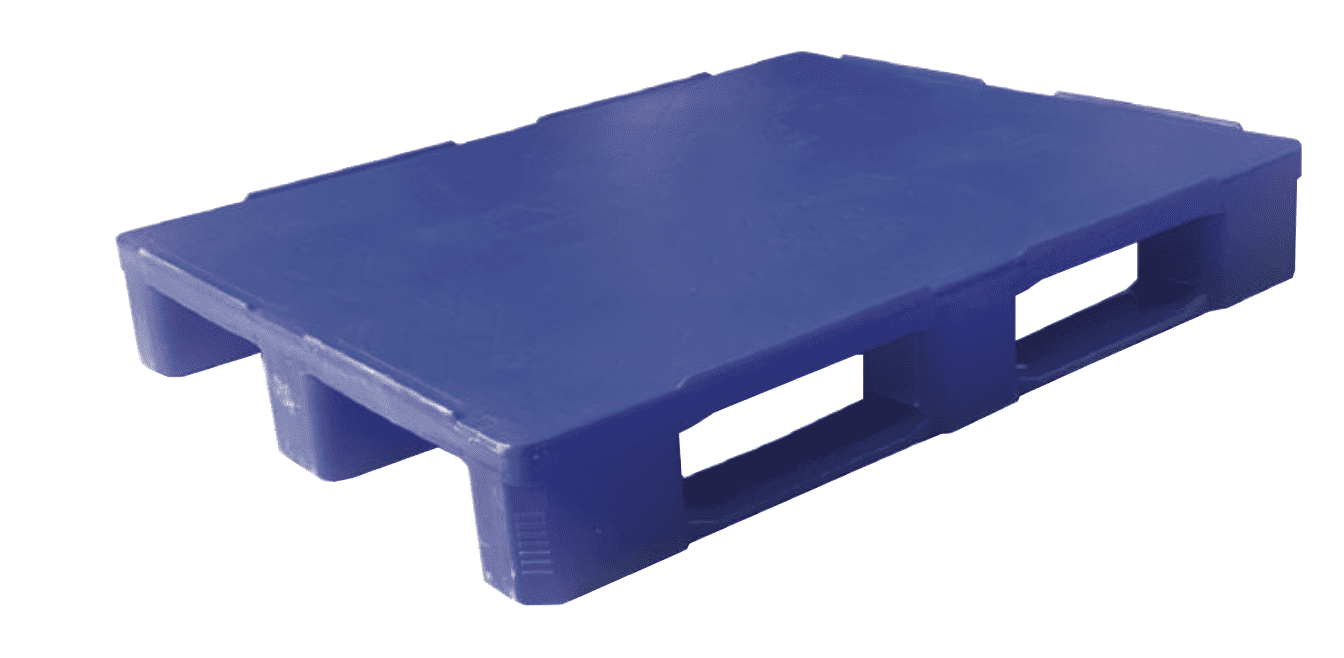

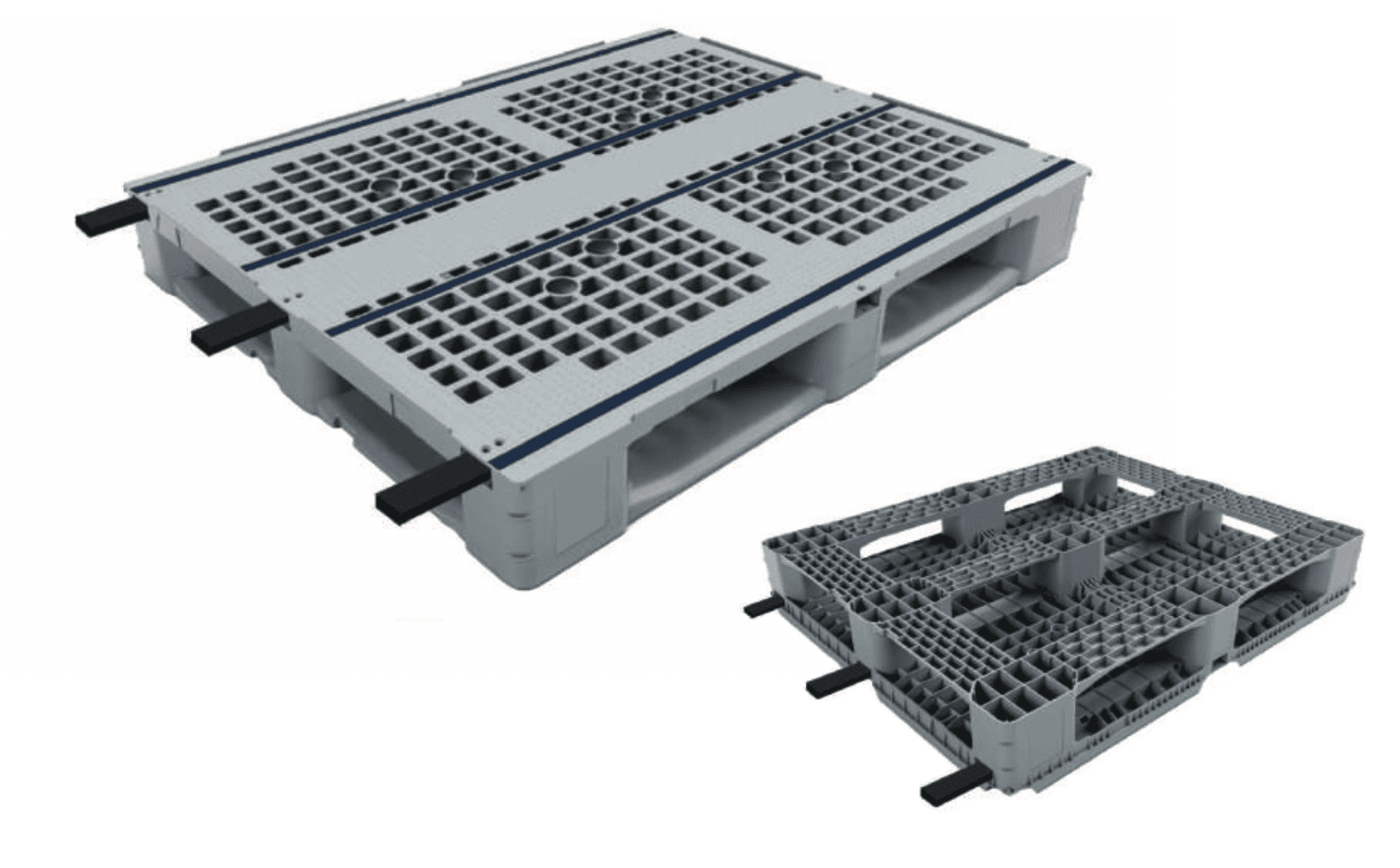

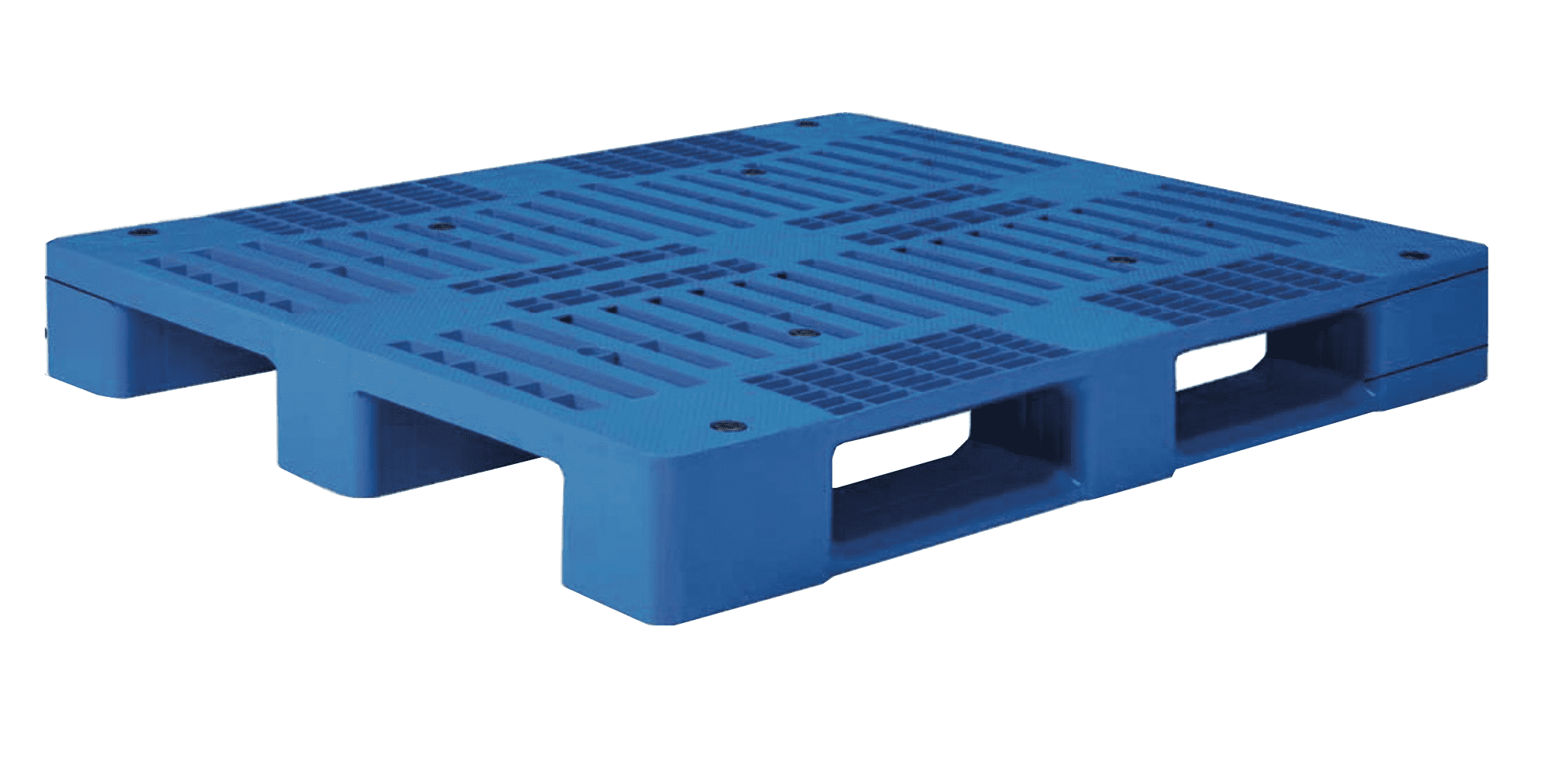

With climate change and environmental issues dominating the news, many businesses are searching for ways to become more sustainable. This climate change might be intimidating for firms that rely on shipping. There are, however, ways to accomplish this without losing productivity or money. Choosing plastic pallets over wooden pallets is a significant step in the right way for novices. While this may appear to be backwards. The pallet UAE is regarded as a valuable asset. Plastic pallets in Dubai were developed with the goal of allowing consumers to purchase pallets less frequently. Pallets can be considered for as depreciable assets in these applications, and the fundamental element driving a purchase choice is return on investment.

A simple comparison of wood versus plastic pallets can get you thinking about your own procedures and requirements.

Wood pallets are made of wood, as the name implies. Regrettably, wood is a limited resource. Wood pallets necessitate the felling of trees, which adds to the worldwide deforestation problem. Plastic pallets, on the other hand, do not require this. Because plastic is man-made, it requires essentially no natural resources. Apart from energy, which has a number of sustainable possibilities, the majority of plastics are carbon-based.

After chopping down the necessary trees for timber, the material must still be converted into wooden pallets. Raw timber must be chemically treated before it can be used for anything, notably pallets used to convey food or pharmaceutical items. It is also required for pallets that will be delivered overseas to avoid introducing non-native insects or germs into a foreign country. If not properly treated, this is harmful to the environment. Plastic pallets have an environmental impact during manufacture, although not as much as timber pallets. Energy consumption is the most expensive aspect of plastic pallet manufacture. Energy, on the other hand, can originate from renewable sources.

Wood pallets are less expensive to purchase than plastic pallets. This is rapidly balanced by the deterioration of wooden pallets’ durability. Wooden pallets can withstand six travels on average. This figure may be lower if the pallets are damaged during shipment and cannot be reused even a few times, costing more money and contributing to the creation of timber and chemical treatments. Pallets made of plastic are significantly more stable. They may make up to 250 rounds before being declared dangerous or otherwise unsuitable. Even pallets at the bottom end of this scale will last longer than wooden pallets. This means you don’t have to replenish as frequently, and you can get the most out of your pallets over a much longer length of time. This also helps to offset the initial cost of plastic pallets.

While wood pallets are biodegradable, the rate at which a corporation uses them diminishes the benefits. It takes around thirteen years to totally decompose. The wood has not been exposed to sunlight, weather conditions, or decaying agents such as fungi or bacteria for an extended period of time. Plastic pallets, on the other hand, are recyclable. They may be taken to a partnering company and melted down to be transformed into something new when they are no longer fit for use, whether due to a fracture or plain wear and tear.

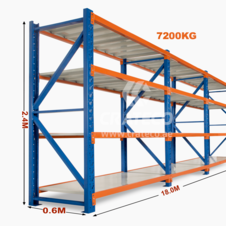

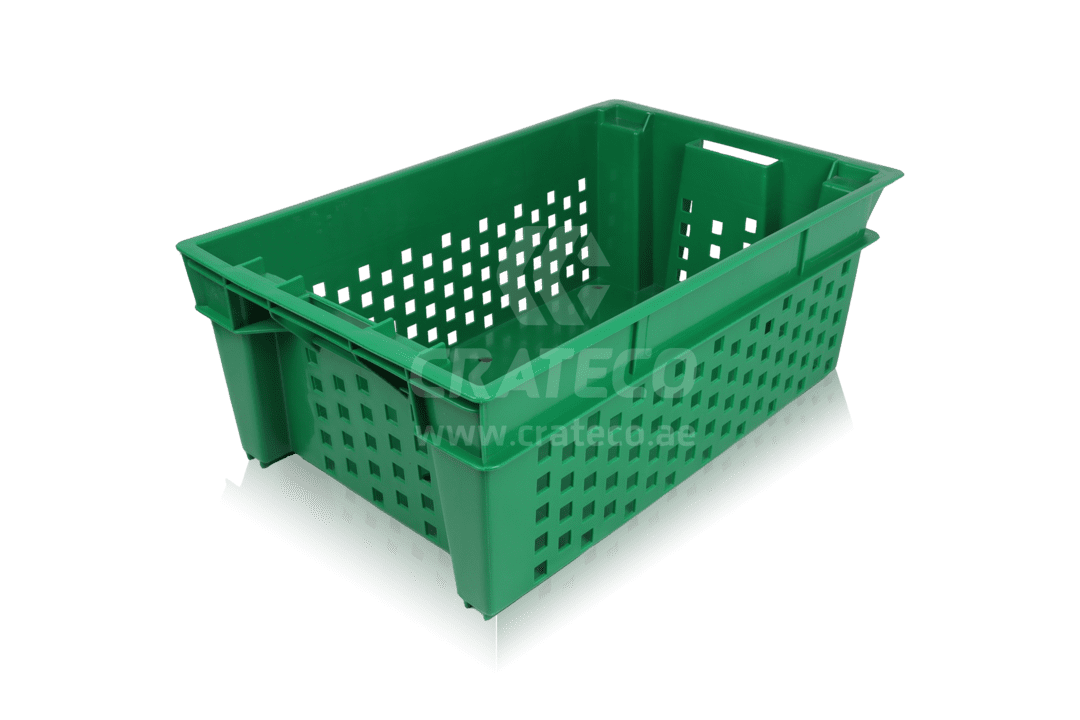

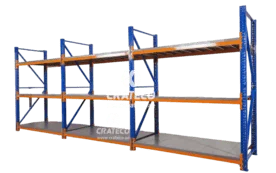

Crateco’s plastic pallets reduce expenses by 75% while improving internal logistics performance. They are more cost-effective than wooden pallets and single-wall plastic pallets, in addition to improving the life of the items. Crateco has variants that can withstand rack weights of up to 2,000 kg without distortion.